Plastics play an important role in all sectors. It can be used for window frames or floors in construction, as packaging in the food chain and as a raw material in consumer goods. Plastics are often made from fossil fuels and do not usually decay in nature. This makes it even more important to close the plastic cycle.

This article discusses the opportunities and barriers to make plastics circular. In addition, various tools are offered for entrepreneurs who want to start working with circular plastic.

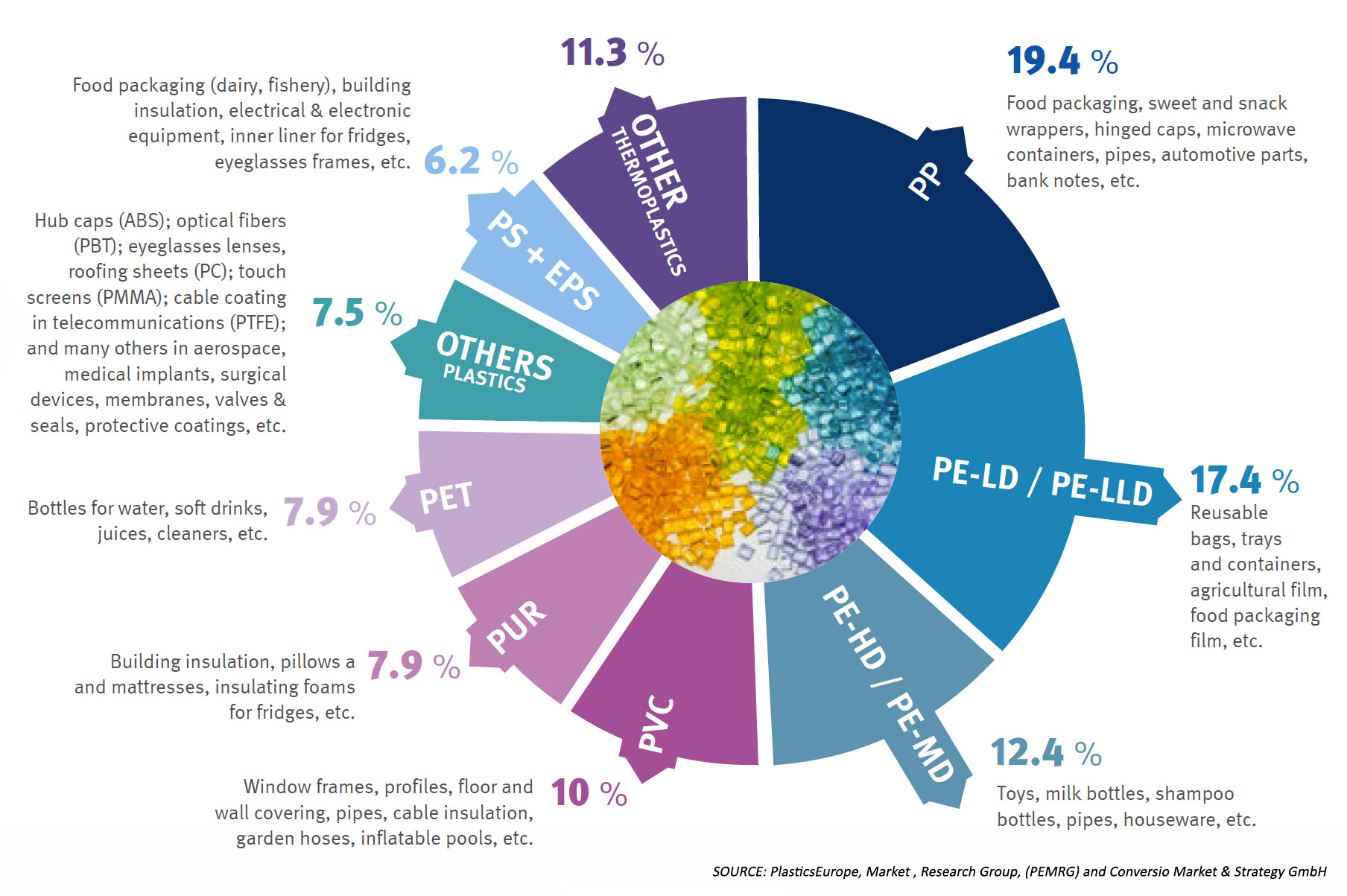

Figure 1: The applications of different types of plastic in Europe (PlasticsEurope, 2020)

Opportunities

There are five strategies on which many entrepreneurs and administrators are focusing in order to achieve a circular application of plastics:

- Avoiding unnecessary use by handling plastic products and packaging as sparingly as possible;

- Designs for reuse, such as a mug that can be used instead of a quantity of disposable cups;

- Designs for high-quality recycling of products or packaging, such as plastic trays made from monomaterials.

- Targeted collection, sorting and recycling of plastic, so that it can be reused at a high quality level;

- Business models for optimal use, such as renting products instead of selling them.

Below are three examples of companies working with these strategies.

Sleeping with a good conscience on an Auping mattress

In 2019, Auping won the Circular Award Business with the development of the Revive mattress, which is fully recyclable. In the Netherlands, 1.5 million mattresses are discarded every year. Mattresses are poorly recyclable and most of them are currently incinerated. The ‘Revive’ mattress, which was developed in collaboration with DSM-Niaga, offers the solution to this problem. It is a high-quality mattress of which all materials are suitable for reuse in a new mattress. The company also offers the mattress in a lease construction (Auping, 2019).

Companies looking for more examples of circular products and companies can take a look at the Kenniskaart article about Circular Companies.

Ioniqa competes with recycled PET

Every year some 50 million tonnes of PET plastic in the form of packaging or clothing disappears from landfills or incinerators. Indeed, many plastic packaging is difficult to recycle mechanically due to its multilayer design and dyes. Several brand owners have expressed the ambition to include more recycled plastics in their packaging. The Eindhoven-based company Ioniqa has now developed a chemical technique to recycle multilayer PET plastics (such as packaging trays) at commercial rates and at high quality. In 2018, the company signed a partnership with Indorama, Coca-Cola and Unilever, which now makes part of its packaging from Ioniqa’s recycled raw material (Ioniqa, 2019).

Entrepreneurs who specifically want to work with the production and recycling of packaging materials can contact the Dutch Knowledge Institute for Sustainable Packaging and NedVang.

Boels Rental lets plastics be used optimally

The growth of Boels Rental shows that there is a good earning model in hiring out articles. The company grew from 4 garage boxes in 1977 to 2600 rental locations in 2020. Initially, the company focused on tools, but nowadays plastic articles, such as event furniture and sanitary installations, make up an important part of its product range. When purchasing products, Boels Rental pays specific attention to the duration of use in order to be able to rent out articles for as long as possible. In this way, Boels increases the effective use of raw materials (Boels, 2020).

Companies that want to start hiring out articles can seek advice from Renting Netherlands, the sector organisation for the Dutch rental market.

Ecological and Economic Profit

Circular use of plastics reduces greenhouse gas emissions and pollution from micro and macro-plastics, which is positive for the environment. The production of plastics releases greenhouse gases. At the same time, only 15 to 17% of plastics are recycled after use. Most of them are incinerated after use in waste incineration plants, where greenhouse gases are again released. A small part disappears into the environment, where it pollutes the food chain and natural systems. If all the plastics in the Netherlands were recycled at a high quality level, this would save 1 million tonnes of CO2 emissions and relieve the burden on ecological systems (TNO, 2019).

Circular use of plastics can lead to profits, because raw materials and products retain their value and fewer new raw materials need to be mined. In the ideal situation, a solution can even be found, which means that fewer quantities or no product at all need to be made. If this cannot be prevented, it is important to recycle the plastic in a high quality way. Most types of plastic can technically already be recycled if they are supplied as pure electricity. A lot of value can therefore be gained by setting up effective logistics. Unsorted sources of plastic can be reused with chemical recycling, but this is still under development.

Barriers

Despite the opportunities for circular plastics, there are still three factors hindering their development: awareness, technology and cooperation.

Awareness

Plastics are such an integral part of people’s daily lives and the production processes of companies that closing their cycles is drastic. A good example is the use of the aforementioned plastic cups with the coffee machine in the office. While the alternative, sturdy glasses and cups, has long been available, it requires a change in use and the infrastructure to keep them clean, to make this transition. Greater awareness of the problems of plastic consumption and the alternatives is essential to make this transition. However, research also shows that awareness alone is not enough to bring about a change in behaviour. Other motivational factors, such as price, convenience, habituation and cultural norms are also important.

Technology

Due to its specific properties, plastics are difficult to replace with other materials, so high-quality recycling is important in order to close cycles of plastics. The challenge in recycling is that plastics often contain adhesives, dyes and other additives in addition to carbon compounds. With conventional recycling, these remain in the mix. In chemical recycling, a collection of promising technologies, it is potentially possible to degrade plastics into the smallest chemical building blocks, from which new monomers and polymers can then be made. Other substances can be filtered out. Investments are needed to enable innovation, further development and upscaling of chemical recycling.

In 2018, the central government, the Province of Friesland, the Waste Fund Foundation and the Packaging Waste Fund set up the National Test Centre Circular Plastics (NTCP). The NTCP is a not-for-profit organisation that contributes to a 100% closable plastic cycle through independent testing, research and advice. The aim is that plastic is not thrown away or burned, but is reused sustainably in its original application. With its test facility for the sorting and washing process on a pilot scale, the NTCP is the first independent test centre in Europe with machines representative of industrial installations. The practical testing and experimentation with real waste streams provides a structural data collection that helps customers achieve their circular objectives.

Figure 2: The hall in which the processing line of the National Test Centre Circular Plastics is built (NTCP, 2019).

Collaboration

Plastics often go a long way from production to use. As a result, closing this chain also requires cooperation with all chain partners. An example is the standardisation of the types of plastic used for packaging. Currently, dozens of types of plastic are used in supermarkets, all with a specific function. Because of this diversity, these plastics are difficult to recycle. If the packaging producers, suppliers and retailers together decided to use some of these types of plastic, this would significantly improve recycling, without sacrificing much in terms of functionality. An initiative to improve this cooperation was in the past the Plastics Recycling Chain Agreement, in which social initiatives, companies, knowledge institutes and governments are linked together in a joint process. In the meantime, a joint programme has been launched within the framework of the Raw Materials Agreement to stimulate circular innovations in the plastics cycle: the Circular Economy Implementation Programme. This is based, among other things, on the Plastics Transition Agenda. Concrete cooperation agreements have been concluded at national (Plastic Pact NL) and European level (European Plastic Pact).

Policy

In its drive for a circular economy, the European Commission adopted a strategy in 2018 to ensure that all plastic packaging can be reused or recycled by 2030. Furthermore, the use of microplastics should be reduced. The European Parliament reinforced this strategy by voting for a total ban on some disposable items, such as plastic cups and signs, by the end of 2018 (EC, 2018).

The Dutch government is also active in the field of plastics, with the aforementioned Implementation Programme Circular Economy, Chain Agreement on Plastic Recycling and the Plastic Pact NL. This pact was signed in 2019 by State Secretary Van Veldhoven and more than 75 parties, including many plastic production and application companies. The pact contains four concrete objectives for 2025. Firstly, 20% less plastic must be used in 2024 than in 2017. Secondly, all products and packaging must be designed to be fully recyclable. Thirdly, at least 70 percent of the single-use plastic must be recycled at a high quality level. Finally, by 2025, 35 percent of all single-use plastic products and packaging must be made of recycled plastic. These targets accelerate the implementation of the EU Plastic Strategy (I&W, 2019). A similar European Plastic Pact has recently been signed by more than 90 parties, aimed at cross-border cooperation, knowledge and experience sharing and harmonisation in tackling the plastics cycle (I&W, 2020).