The transition to a circular economy requires companies to manage resources intelligently and efficiently, shifting from linear to circular business practices. But what does circular business mean, and how do you develop a circular business model? On this page, we explain and provide practical guidance to help you get started.

A circular business model

A circular business model can be defined as a strategic approach where a company creates value by designing, producing, and delivering products, services, and materials with the aim of minimizing waste, extending product lifespan, and maximizing the reuse of resources.

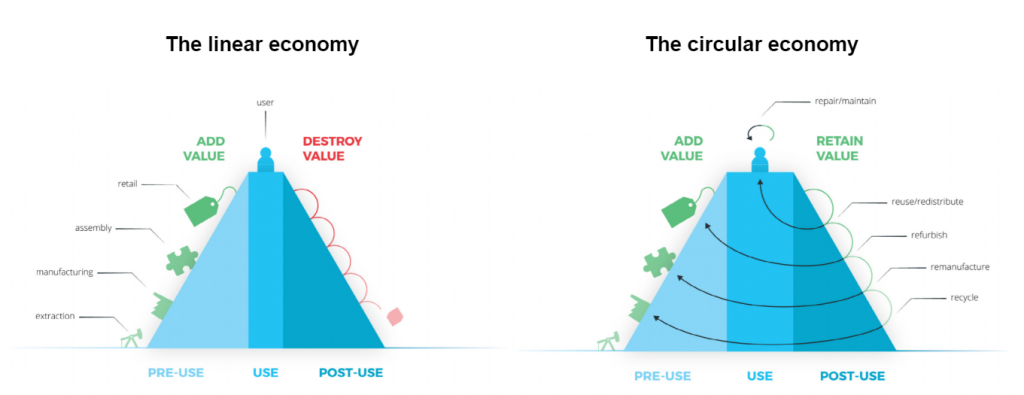

In a linear economy, new raw materials are typically extracted for products, processed, and sold. After consumer use, the product becomes waste. In a circular economy, companies aim to optimize the value of resources, avoiding waste or destruction. This starts with design; smart design can save resources, facilitate easy repair, or enable recycling after use. Products and services are structured for maximum usage. If a product breaks, it is repaired. If repair is not feasible, new products are created. If all else fails, the resource exits the economy as waste, but this should be minimized as much as possible. The Value Hill visualizes strategies to achieve this.

Figure 1: The Value Hill (Achterberg, Hinfelaar and Bocken, 2016).

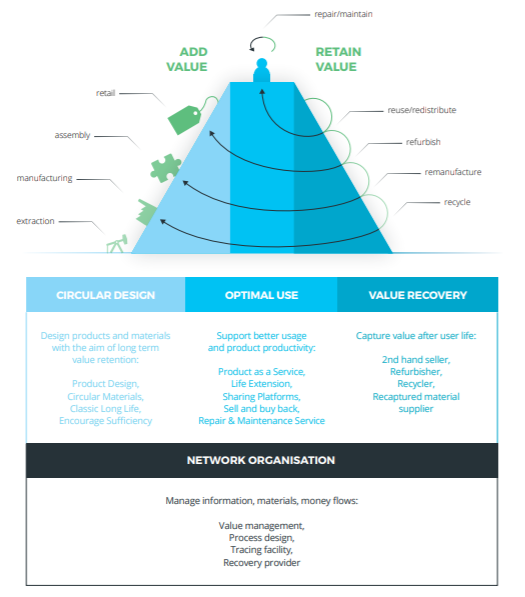

The Value Hill categorizes circular business models into four groups:

- Circular Design: Companies design products to last longer, be easily maintained, repaired, and recycled. They also use sustainable materials, such as biobased resources or recycled materials.

- Optimal Use: Companies develop strategies to optimize product use and extend product lifespan. This may include promoting proper maintenance of items like bikes or facilitating car-sharing.

- Value Recovery: Companies generate revenue by transforming used products into new products, usable components, or raw materials.

- Network Organization: Companies develop products and services that promote and facilitate the strategies mentioned above.

Figure 2: Circular business activities on the Value Hill (Achterberg, Hinfelaar and Bocken, 2016).

Circular Design

Circular Design models focus on the development phase of a product.

We design products to have a longer lifespan and to be easily maintained, repaired, upgraded, renewed (refurbished), remanufactured, or recycled. Additionally, we develop or use new materials, such as bio-based or fully recyclable materials.

Examples of business models in this category (Achterberg, Hinfelaar and Bocken, 2016):

- Product Design: Developing products designed for easy maintenance, repair, and renewal, such as a modular product.

- Long Lifespan: Creating products with an extended lifespan.

- Circular Materials: Supplying input materials like renewable energy, bio-based materials, or fully recyclable materials.

- Sufficiency: Justifying lower volumes through a higher price per product.

Fairphone

Fairphone is a social enterprise designing and producing fair and sustainable smartphones, focusing on four themes: fair labor conditions, sustainable design, reuse, and recycling. During the development of the first Fairphone, the focus was on sustainability and labor conditions in procurement and assembly processes. The subsequent models (2 & 3) adopted a modular design, allowing Fairphone parts to be easily replaced or upgraded. While Fairphone currently sells phones, they have also developed a financeable circular business model, Fairphone-as-a-Service, the lessons, contract, and financial model of which are publicly available (Fischer en Achterberg, 2017)

Optimal Use

Optimal Use business models focus on the usage phase of a product, aiming to optimize product use, extend product lifespan, and conserve resources. These models enable retaining product ownership (e.g., offering a product as a service rather than selling it) and taking responsibility for the product throughout its entire lifespan (e.g., offering repair and maintenance services or add-ons that extend the lifespan). These business models create a shift from selling products to selling the function of these products.

Examples of business models in this category (Achterberg, Hinfelaar and Bocken, 2016):

- Product-as-a-service: Delivering product performance instead of the product itself through a combination of products and services. The service provider retains ownership of the product;

- Sell and buy-back: A provider sells a product under the condition that they will buy it back after a certain period, allowing providers and consumers to reuse the product;

- Sharing platforms: Optimizing product use by enabling customers to share product use, access, or ownership;

- Lifespan extension: Extending the usable lifespan of products and components through repair, maintenance, or upgrades;

- Support lifecycle: Selling consumables, spare parts, and add-ons to support or extend the lifecycle of products.

Bundles

Bundles sells laundry services instead of washing machines. Customers pay a fixed monthly fee and an additional price per wash for a sustainable washing machine. By attaching a smart meter to the machines, Bundles can monitor their usage. In the Wash-App, customers can view their usage and receive tips to reduce the total costs of washing, including energy, water, and detergent consumption. This reduces costs for the customer and benefits the lifespan of the machine. This combination creates a financial incentive to prolong the lifespan of washing machines.

Value recovery

Value Recovery business models focus on the output and added value of a product after its usage phase. Companies using these models generate revenue by converting used products into new products, usable components, or raw materials. The development of reverse logistics is essential for this model.

Examples of business models in this category (Achterberg, Hinfelaar and Bocken, 2016):

- Second hand seller: Sale of used products;

- Innovator: Refurbishing and remanufacturing used products with the aim of reselling them;

- Reclaimed materials supplier: Selling recovered materials and components instead of new or recycled materials;

- Recycling facility: Transforming waste into raw materials, generating extra revenue through innovation in recycling technology.

Blackbear Carbon

Blackbear Carbon transforms discarded car tires into carbon black, an industrial product used in rubber (70-80%) or as pigment for plastics, mascara, paint, and ink. Annually, Blackbear Carbon collects around 1.5 billion used car tires, preventing them from ending up in landfills and causing potential health problems. Through the developed process, Blackbear can establish a circular loop and deliver a product of comparable quality to traditional suppliers. Hence, an alternative for raw materials (Ewen et al., 2017).

Network Organisation

The models in the above categories cannot individually establish a circular economy. Collaboration is indispensable. Network Organization models involve business activities that support the coordination and collaboration of circular networks.

Currently, companies like Recover-E and Dutch aWEARness have taken on the role of chain directors, but there is also a need for joint coordination that requires new ways of organizing.

Examples of business models in this category (Achterberg, Hinfelaar and Bocken, 2016):

- Recovery provider: Sale of collection systems and collection services to recover usable materials from discarded (by)products;

- Asset tracing & monitoring: Services for tracking, monitoring, and trading products, components, and materials;

- Contract management: Facilitating the creation, handling, execution, and/or enforcement of contracts;

- Financial services: Services managing financial flows, such as facilitating supply chain financing, debtor management, inverse factoring, creditworthiness checks;

- Data services: Services managing, coordinating, and facilitating information flows.

Circular Service (CiSe) platform

The Circular Service (CiSe) platform functions as a digital payment and administration system for circular businesses. The success of circular chains depends on long-term agreements, collaboration, and trust among chain partners. This often involves high administrative costs. The CiSe Platform utilizes new technologies, such as blockchain and smart contracts, to drastically reduce these costs, providing the requested transparency and offering financiers new ways to finance the circular economy. The preliminary results of this approach are promising (Achterberg, 2019).